Rod mills are used in an open circuit between crushing and the ball mill. They often operate in wet and where the pulp contains up to 50% solid by mass. This machine is equally very applicable to dry where it could take a feed that has achieved 6% moisture. As such,

2016年1月1日 The designs of tubular mills loaded with steel rods along its length as the grinding medium are described in this chapter. Details of operation and computations of

2022年9月11日 Citation: Anticoi, H.; Guasch, E.; Pérez-Álvarez, R.; de Luis-Ruiz, J.M.; Oliva, J.; Hoffman Sampaio, C. Rod Mill Product Control and Its Relation to Energy

Explain the use of rod mills in mineral industry. Explain rod mill operation. Recognize different design parameters of rod mills. Explain problems associated with rod milling.

2016年5月31日 Free Metallurgical Help Rod Mills Previous Next The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing

2018年4月5日 EF8 Rod Milling a study of rod mill operations shows that rod mill performance is affected by the attention given to preparation and feeding a uniform top

2017年7月4日 Simulation of Batch Rod Milling using the Linearized Grinding Model Material Transport Through Rod Mills Residence Time Distribution Analysis Effect of Operating Variables on Material Transport

Several methods to comminute soil have been developed: mortar, pestle, and sieve by hand; milling machines using rods, balls, hammers, and air jets together with soils in a jar; and

2019年10月9日 sieves, by hand; using milling machines, with rods, balls, hammer, and air jets applied to soils in a jar; using mechanical crushers, powered by electricity to ap- ply

2015年6月1日 This study aims to determine whether the rod size, milling time or a combination of both can control the size distribution and properties of the grains of a

2016年1月1日 Introduction Tubular tumbling mills loaded with rods as the grinding media are used for primary grinding of rocks and minerals. Rods are placed parallel to the length of the mill, their length being about 150 mm shorter than the inside length of mills.

2022年9月11日 the tumbling mill product in terms of particle size and mass balance [13,14]. Therefore, this study aims to identify which parameters can be used to control rod milling operations in order to obtain a material with a certain size characteristic at a lower energy consumption. The material under study is comminuted in rod mills, but for further

In our Special Bar Quality (SBQ) mills we make use of the 3-roll PSM ® (Precision Sizing Mill) technology a high-precision and flexible solution for the finish-rolling of bars. With the PSM ® one family, rolling in the

2017年7月4日 Simulation of Batch Rod Milling using the Linearized Grinding Model Material Transport Through Rod Mills Residence Time Distribution Analysis Effect of Operating Variables on Material Transport

2023年6月15日 A rod mill uses steel rods as the grinding media in tumbling mills is an efficient means to feed ball mills a product finer than could be made in a crusher but coarser than could be made in a ball mill. The

2019年10月9日 We developed a planetarytype rod mill that can improve the comminution working efficiency, prevent the generation of soil dust, and make it easy to clean the used jars. Clods are broken by this device into fine-grained soil par- ticles with sizes of less than 2 mm in diameter within 2 min.

Pazesh et al. (2017) studied the relationship between comminution and amorphisation of α-latctose monohydrate particles during ball milling under different milling conditions using a planetary ball mill (PM100, RetschCo.) [1] . A jar in the mill rotates twice per revolution of the sun wheel in a horizontal plane.

2015年6月1日 The produced grains examined by sieve analysis and binocular microscope show that the entire rod size and 30-minute milling time yielded grain enlargement as a result of van der Waals forces among

DRY GRINDING PROCESS USING A ROD MILL, be controlled by rod size, milling time or a combination of both. Milling experiments had been carried out using rod of 9.8, 23.8, and 46.0 cm

2019年10月9日 sieves, by hand; using milling machines, with rods, balls, hammer, and air jets applied to soils in a jar; using mechanical crushers, powered by electricity to ap-ply jaws, gyrating rods, rollers, and disc and edge runners. me- Comminution chanisms have not been precisely explained for each type of mill machine. Ad-

2022年9月11日 Citation: Anticoi, H.; Guasch, E.; Pérez-Álvarez, R.; de Luis-Ruiz, J.M.; Oliva, J.; Hoffman Sampaio, C. Rod Mill Product Control and Its Relation to Energy Consumption: A Case Study. Minerals2022,12, 183. https://doi/10.3390/ min Academic Editor: Carlos Hoffmann Sampaio Received: 10 December 2021 Accepted: 28

2015年8月8日 MINERAL PROCESSING MILLING Introduction Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size. It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size.

In our Special Bar Quality (SBQ) mills we make use of the 3-roll PSM ® (Precision Sizing Mill) technology a high-precision and flexible solution for the finish-rolling of bars. With the PSM ® one family, rolling in the

2023年6月15日 A rod mill uses steel rods as the grinding media in tumbling mills is an efficient means to feed ball mills a product finer than could be made in a crusher but coarser than could be made in a ball mill. The

2015年6月1日 The produced grains examined by sieve analysis and binocular microscope show that the entire rod size and 30-minute milling time yielded grain enlargement as a result of van der Waals forces among

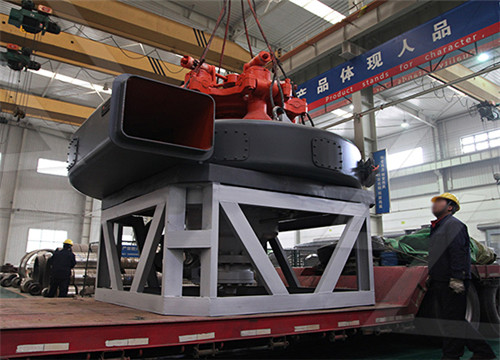

2019年10月17日 Rod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operation.

2019年10月9日 We developed a planetarytype rod mill that can improve the comminution working efficiency, prevent the generation of soil dust, and make it easy to clean the used jars. Clods are broken by this device into fine-grained soil par- ticles with sizes of less than 2 mm in diameter within 2 min.

Rod mill is a tumbling mill characterized by the use of rods as grinding media and frequently used in primary grinding (Gupta and Yan, 2006). The rod is more demanded than the ball due...

Several methods to comminute soil have been developed: mortar, pestle, and sieve by hand; milling machines using rods, balls, hammers, and air jets together with soils in a jar; and crushers using jaws, gyrating rods, rollers, electricity, disks, and edge runners.

2019年10月9日 Several ways to comminute a soil have been devised: using pestles, mortars, and sieves, by hand; using milling machines, with rods, balls, hammer, and air jets applied to soils in a jar; using mechanical crushers, powered by electricity to ap- ply jaws, gyrating rods, rollers, and disc and edge runners. me- Comminution chanisms have not

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين